MTSCO continues to monitor global industrial market trends. Recent industry data shows that the global heat exchanger market is experiencing strong growth, expected to reach $25.5 billion by 2030, with a compound annual growth rate (CAGR) of 5.3%.

Key Industrial Sectors Driving Future Demand

This growth is mainly driven by the continued expansion of core industrial sectors such as chemicals, oil and gas, and power generation. For example, the chemical industry alone makes up about 20% of the market share, with processes such as distillation and evaporation that rely heavily on efficient heat transfer. Projects in these sectors place strict demands on equipment reliability and efficiency over the long term, placing strategic material selection at the core of project success.

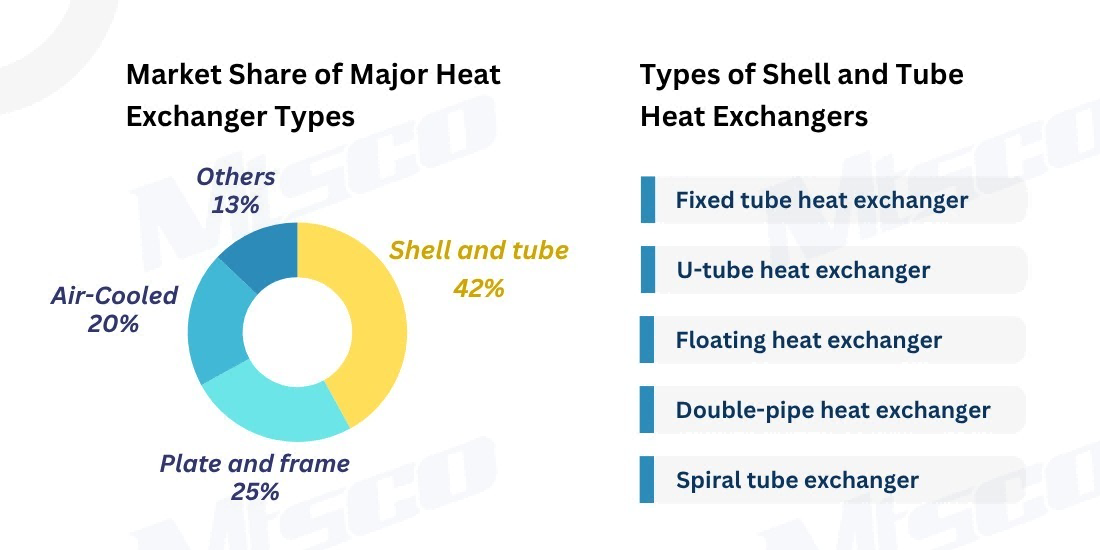

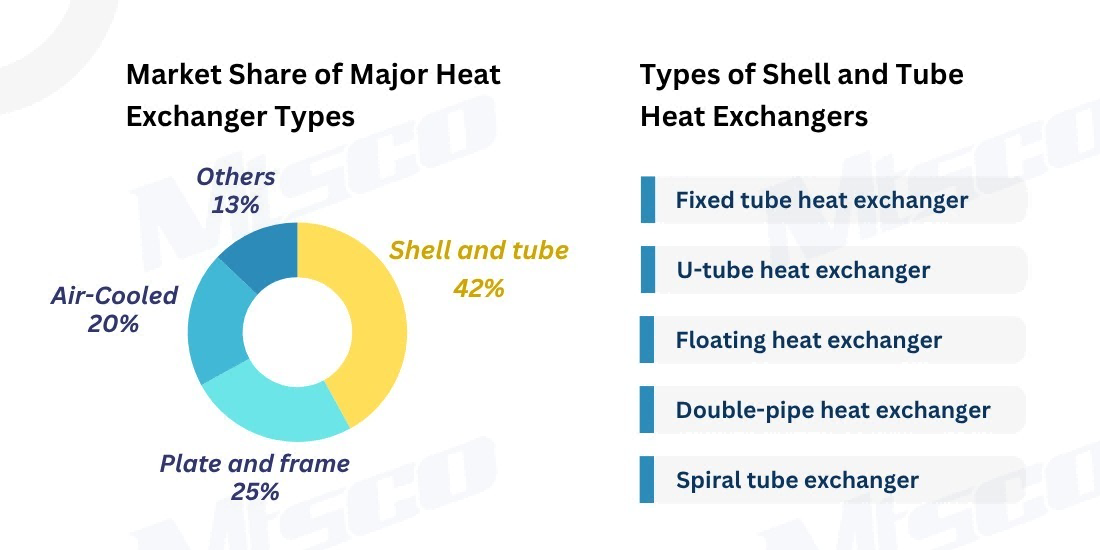

Shell and Tube Heat Exchangers Remain a Market Leader

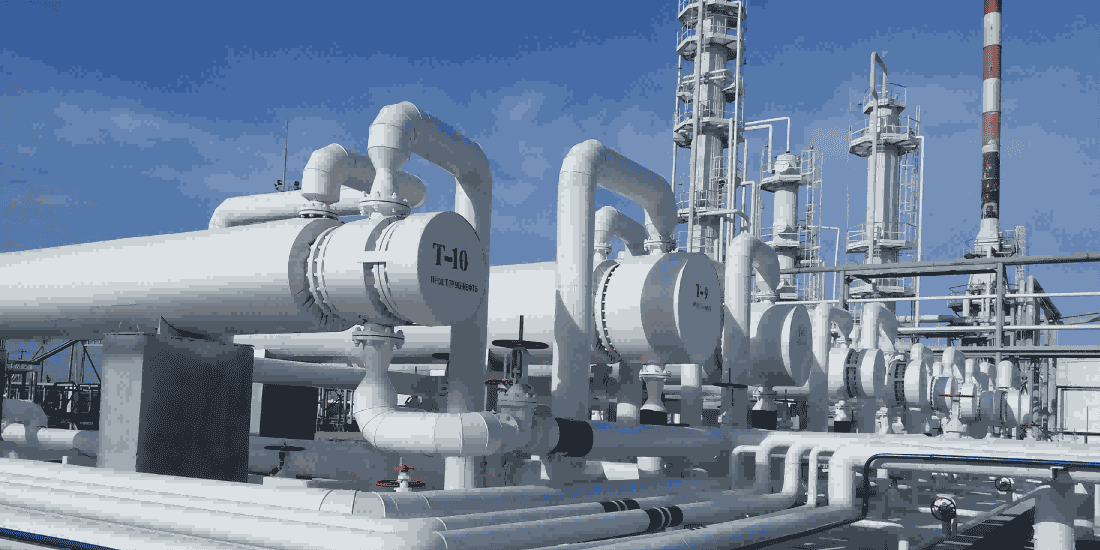

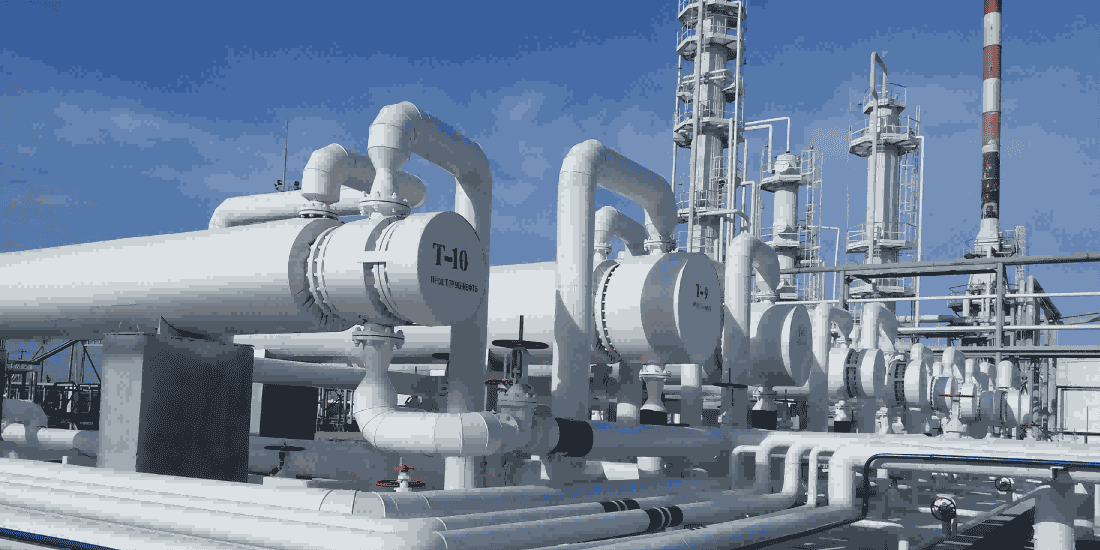

Among various heat exchanger types, shell and tube heat exchangers hold about 42% of the market share, making them a true industrial mainstay. Their strong structure and flexibility are key advantages. Under harsh operating conditions, stable operation of this equipment is essential, directly affecting the safety and efficiency of the entire production line. Therefore, investment in the materials of core components is essential to ensuring the long-term value of a project.

MTSCO Material Solutions

MTSCO offers complete, high-performance material solutions for major heat exchangers, ensuring optimal performance under tough operating conditions.

Core Materials: Stainless steel, duplex steel, and nickel alloy (Monel, Inconel, Hastelloy, etc.)

Products and Applications

Shell and Tube Heat Exchangers: Seamless/Welded Tubes (for core heat exchange tubes); Plates/Forgings/Flanges (for structural components)

Plate and Frame Heat Exchangers: Specialty Plates (for core plates); Bars (for frame components)

Sharing these industry insights is intended to help you achieve project success. We are happy to discuss with your technical team how to select the best long-term material solution for your specific application.