| Availability: | |

|---|---|

| Quantity: | |

Stainless Steel 316L/ 316Ti Encapsulated Tubing with FEP

Material: TP304/L, TP316/L, S32205, S32507, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Outer Diameter: 1/4'', 3/8'', 1/2''

Wall Thickness: 0.035'', 0.049'', 0.065''

Hole count: Single/Multi Core

Length : According to customers' needs, up to 33000fts/coil

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

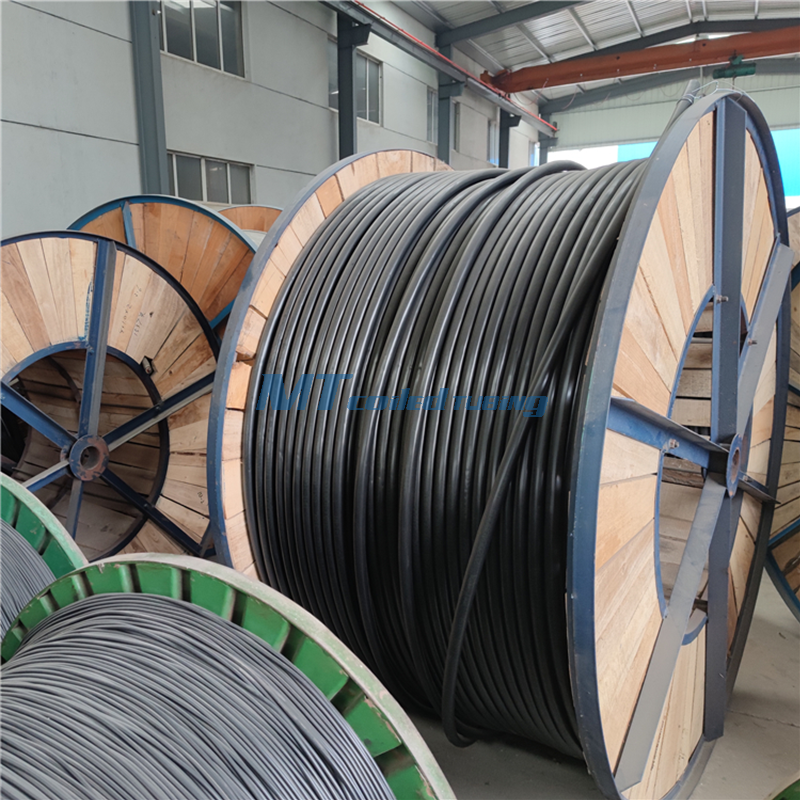

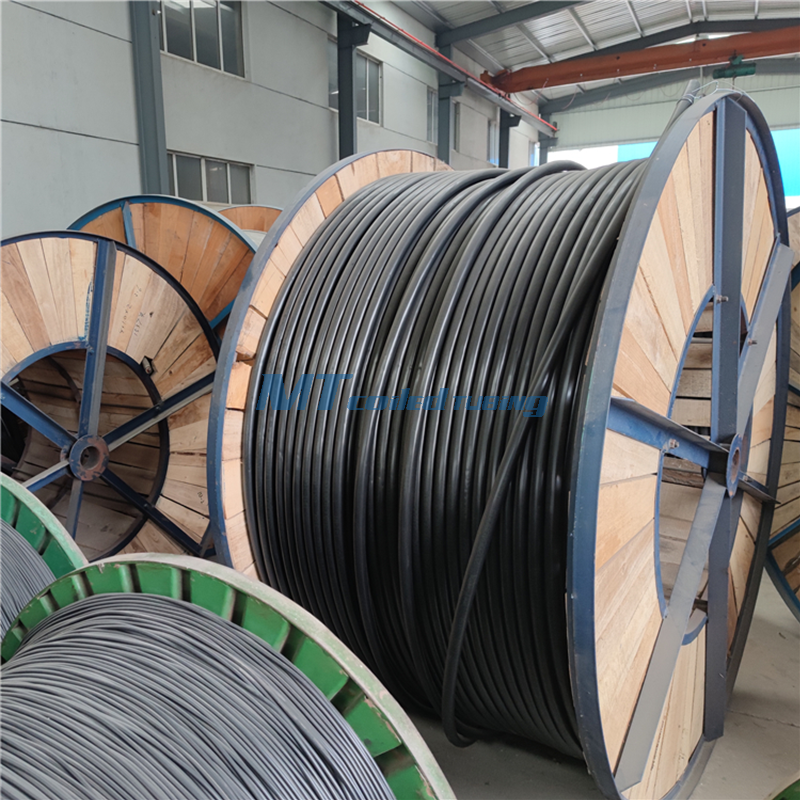

Package: Wooden or iron reel

Plastic Packaging Materials | Abbreviation | Temperature℃ |

Ethylene Tetrafluoroethylene | ETFE | -60℃~150℃ |

Fluoronated Ethylene Propylene | FEP | -110℃~200℃ |

High Density Polyethylene | HDPE | -60℃~100℃ |

Perfluoroalkoxy | PFA | -80℃~260℃ |

Modified Polypropylene | PP | 30℃~150℃ |

Polyvinylidene Fluoride | PVDF | -30℃~150℃ |

Thermoplastic Vulcanizating | TPV | -30℃~150℃ |

Nylon11 | PA11 | -30℃~150℃ |

|  |

An increasing number of projects in the oil service industry require the use of continuous lengths of encapsulated tubing. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex chemical injection lines. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.

Stainless Steel 316L/ 316Ti Encapsulated Tubing with FEP

Material: TP304/L, TP316/L, S32205, S32507, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Outer Diameter: 1/4'', 3/8'', 1/2''

Wall Thickness: 0.035'', 0.049'', 0.065''

Hole count: Single/Multi Core

Length : According to customers' needs, up to 33000fts/coil

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

Package: Wooden or iron reel

Plastic Packaging Materials | Abbreviation | Temperature℃ |

Ethylene Tetrafluoroethylene | ETFE | -60℃~150℃ |

Fluoronated Ethylene Propylene | FEP | -110℃~200℃ |

High Density Polyethylene | HDPE | -60℃~100℃ |

Perfluoroalkoxy | PFA | -80℃~260℃ |

Modified Polypropylene | PP | 30℃~150℃ |

Polyvinylidene Fluoride | PVDF | -30℃~150℃ |

Thermoplastic Vulcanizating | TPV | -30℃~150℃ |

Nylon11 | PA11 | -30℃~150℃ |

|  |

An increasing number of projects in the oil service industry require the use of continuous lengths of encapsulated tubing. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex chemical injection lines. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.